Forecast Configuration

Introduction

Forecast calculations in 4C Supply® can be provided forecast configuration parameters. Forecast configuration parameters can be included in the scenario specification or set on the fly before running the forecast calculation.

Notes

Forecast configuration parameters are forecast calculation inputs, thus become part of the forecast calculation report and are displayed at a high level in the forecast overview.

User can select to show or hide the logs from the last forecast calculation by clicking Show Logs or Hide Logs at the top of the forecast calculation screen.

Demand Configuration

Computation Interval in Days

The computation interval can be set between 1 and 7 days. A computation interval of 1 will generate forecasts precise to one day by running a longer, more complex calculation. For most forecasting requirements the default interval of 7 days will provide sufficient detail and produce results more quickly.

Report Interval

The Report Interval is the interval used in all Output Reports. In the Demand Configuration Table in the SMART Editor, a value of X Days or 1 Month (Default) can be entered. In the Demand Configuration Tab on the Calculation page, users will select X Days or 1 Month from the drop down.

Note: If selecting X Days, the value must match the computation interval. For example, if 5 days is specified for the computation interval, and a daily report is desired, then a user must specify 5 days for the reporting interval.

Manual Overage

Overage which is manually added to the forecasted root node demand to define the production quantity

production quantity = manual overage x forecasted root node demand + forecasted root node demand

Accepts decimal values (e.g. 0.5) and percentage values (e.g. 50%). If a non-valid entry is made, an input validation error message is shown. The valid range is 0% - 100%.

Manual overage is included as root node demand in production plan validation and can therefore create out of stock risk that is not reflected in the trial supply projection because it doesn't represent any subordinate depot demand.

Manual overage is expected to lead to residual stock at the root node because there is no corresponding subordinate depot demand.

Manual overage impacts the forecasted total scrap, but is not the same parameter.

Confidence used for site buffers

The selected confidence interval determines which cases of the probability distribution are considered in site buffer calculation. The higher the selected confidence interval, the more extreme cases are considered in site buffer calculation. Enrollment buffers are computed to cover the maximum enrollment (per selected confidence interval) in the site shipment lead time.

Further details are provided in the forecast calculation documentation, section site demand forecasting.

Supply Configuration

Prediction Windows

Within 4C Supply, the Prediction Window used is calculated by combining the demand recorded in the Short Window (SW) with the demand captured in the user defined Prediction Window - referred to as the Long Window (LW).

The combined SW + LW determines how far into the future 4C Supply will look ahead from the current date to forecast demand and resupply for the upcoming period.

Example:

Depot to Region Short Window (SW) = 30 days

Site Group Prediction Window (LW) = 30 days

Prediction Window = SW + LW = 60 days

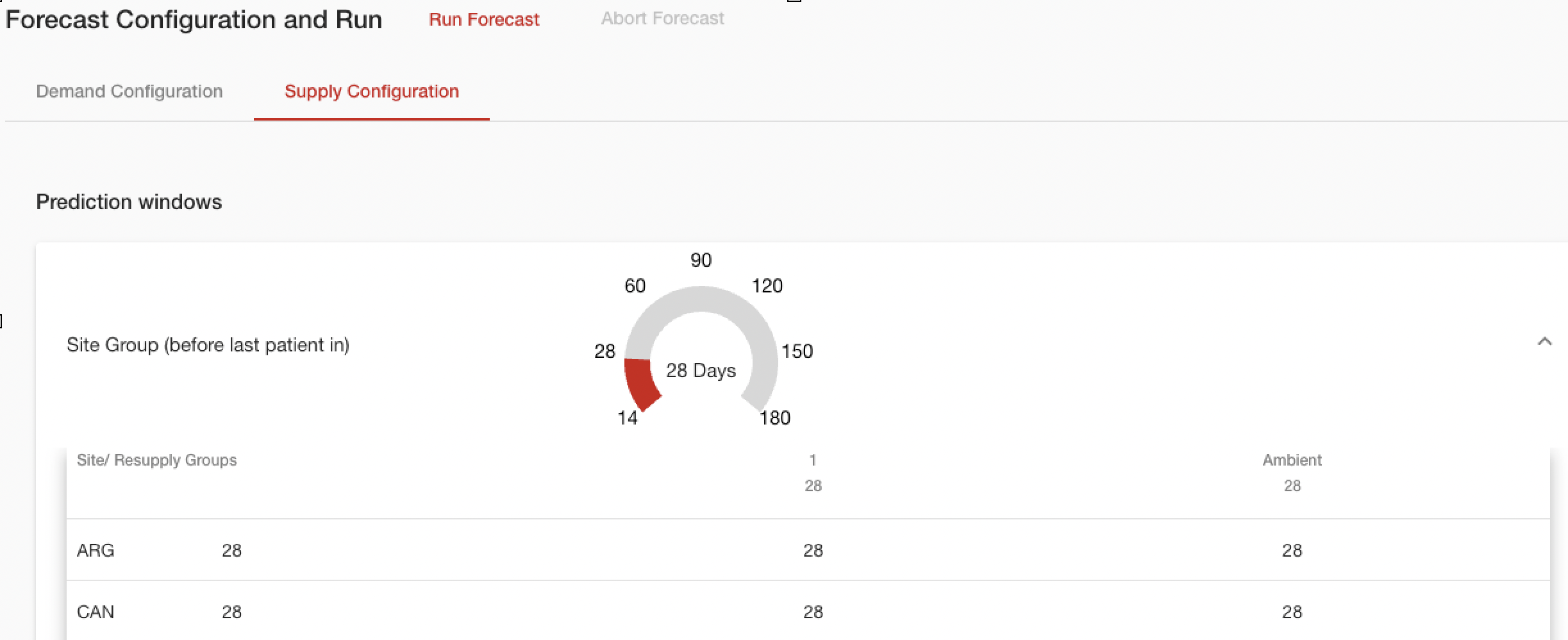

Site Group Prediction Window (or Long Window)

The Site Group Prediction Window (or Long Window) is added to the Short Window to determine the demand period which is covered when site shipments are calculated in the forecast.

Can be defined for the study in the Supply Configuration table.

Can be defined per site in the Site Groups table.

Site Group prediction windows can also be defined statically or dynamically with respect to the Last Patient In event in either the Supply Configuration or the Site Groups table.

Individual Site Group values override study values.

If these values are not defined in the specification they can alternatively be defined from the Supply Configuration tab of the forecast calculation page.

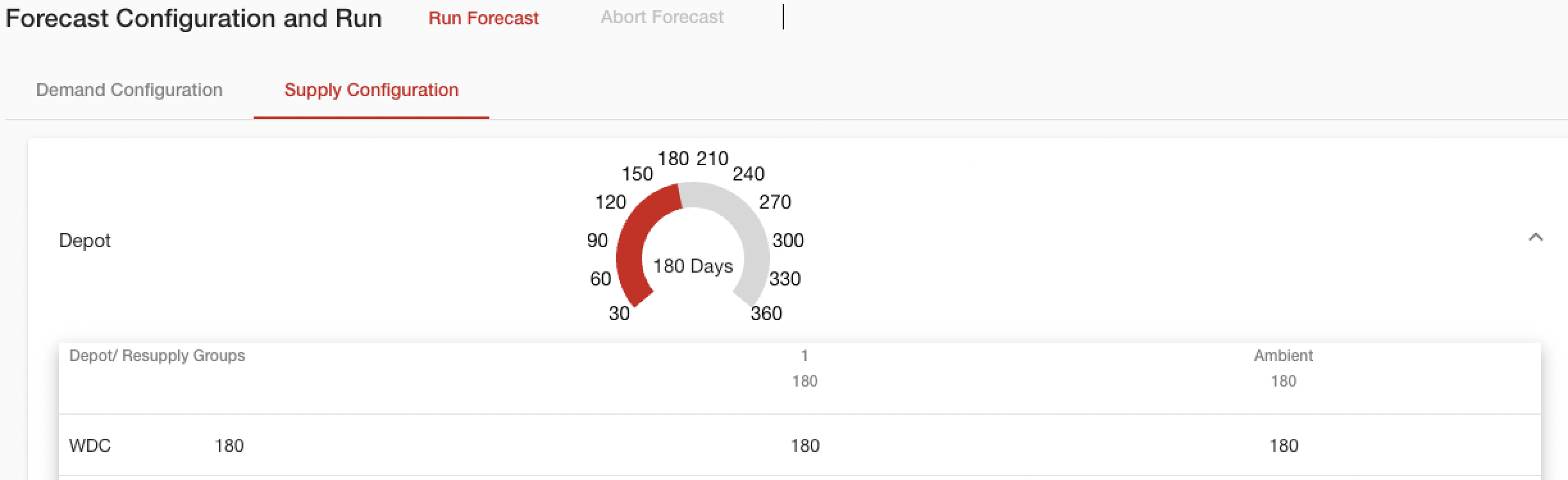

Depot Prediction Window (or Long Window)

The Depot Prediction Window (or Long Window) is added to the Short Window to determine the demand period which is covered when depot shipments are calculated in the forecast.

Can be defined for the study in the Supply Configuration table.

Can be defined per depot in the Depot table.

Individual depot values override study values.

If these values are not defined in the specification they can alternatively be defined from the supply configuration tab of the forecast calculation page.

Inventory Management

Users can specify in the supply configuration on the forecast calculation page of the specification which site resupply logic, RTSM parameter update interval, and resupply trigger should be used in the forecast.

If any of these parameters are defined and saved in the SMART Editor specification,

the specified value is shown in the supply configuration tab of the forecast calculation page,

cannot be updated and

a “snack bar” with label

Note: Value is set in the scenario specification and therefore read onlyis shown.

If any of these parameters are not defined in the SMART Editor specification, the default value is used and can be updated.

Updates to the Inventory management section are saved immediately when made.

Site Resupply Logic

4C Supply® offers 3 Resupply Logic options - Prancer RTSM, Buffer + Prediction, and Buffer-Only. Note, the default setting is Prancer RTSM.

Resupply Logic options are Prancer RTSM, Buffer + Prediction, or Buffer.

If the site resupply logic is Buffer + Prediction, then buffer floor settings are calculated in the forecast for each dispensing unit, site group and RTSM parameter update interval as maximum forecasted unpredictable demand in the site shipment lead time (or Short Window) during the respective RTSM parameter update interval.

If the site resupply logic is Buffer, then buffer floor settings are calculated in the forecast for each dispensing unit, site group and RTSM parameter update interval as maximum forecasted total demand in the site shipment lead time (or Short Window) during the respective RTSM parameter update interval.

If the site resupply logic is Prancer RTSM, the enrollment rate settings are calculated in the forecast for each site group and RTSM parameter update interval as maximum forecasted enrollment rate during the respective RTSM parameter update interval

RTSM Parameter Update Interval

Resupply Parameters can be updated at Yearly, Quarterly, or Monthly (Default) intervals.

Periods where the buffers or enrollment rates are forecasted to be updated are computed according to the specified RTSM parameter update interval.

If the RTSM parameter update interval is Year, then buffer level settings are assumed to remain unchanged in each year after the study start. Year is defined as 01January to 31December. RTSM Parameters would update every 01January that the study is running.

If the RTSM parameter update interval is Quarter, then buffer level settings are assumed to remain unchanged in each quarter after the study start. Quarter is defined as 01January to 31March, 01April to 30Jun, 01July to 30September, and 01October to 31December. RTSM Parameters would update on 01January, 01April, 01July, and 01October.

If the RTSM parameter update interval is Month, then buffer level settings are assumed to remain unchanged in each month after the study start. RTSM Parameters would update on the 1st of each month.

Resupply Trigger

4C Supply® can be configured to trigger a site resupply when the site available inventory falls Below Floor (or Buffer) Value or when the site available is equal to or below the Floor (or Buffer) Value. Default setting is Below Floor.

If resupply trigger = Floor, then resupplies are triggered when site inventory = trigger level or site inventory < trigger level.

If resupply trigger = Below floor, then resupplies are triggered when site inventory < trigger level.