MicroBio Validation Kit - Operating Manual

Introduction

The MicroBio Validation Kit is the standard device used to validate standard 100 litre per minute MicroBio MB1 and MB2 bioaerosol samplers. It provides a simple and cost effective method to ensure the MicroBio samplers are working at peak performance, requiring the minimum of training to use.

This guide provides information needed to validate the MicroBio MB1 and MB2 bioaerosol samplers and maintain the kit.

The MicroBio Validation Kit is not suitable for use with other makes of bioaerosol samplers.

It is not suitable for use with 180 lpm flow rate models:

MB1-HiFlow

MB2-HiFlow

MB2-RSH-HiFlow

Statement of Conformity

We certify that this product complies with EEC DIRECTIVE 2002/95/EC the restriction of hazardous substances; commonly known as the RoHS directive. The validation kit is designed and manufactured under strict management systems compliant with ISO9001:2008 and calibration of the instruments is traceable to national standards.

Warranty

The manufacturer warrants this product to be free from defects in materials and workmanship for 36 months from the date of purchase.

If your product is found to be defective within that period, please contact Cantium Scientific Limited or your local distributor who will arrange for repair of the instrument, or if necessary a replacement.

This warranty does not cover accidental damage, wear and tear, consequential or incidental loss.

Damage caused by cleaning materials and methods not recommended by the manufacturer, use beyond the specification, use in wash down areas, or modifications without prior permission from the manufacturer will invalidate the warranty. This warranty does not affect your statutory rights.

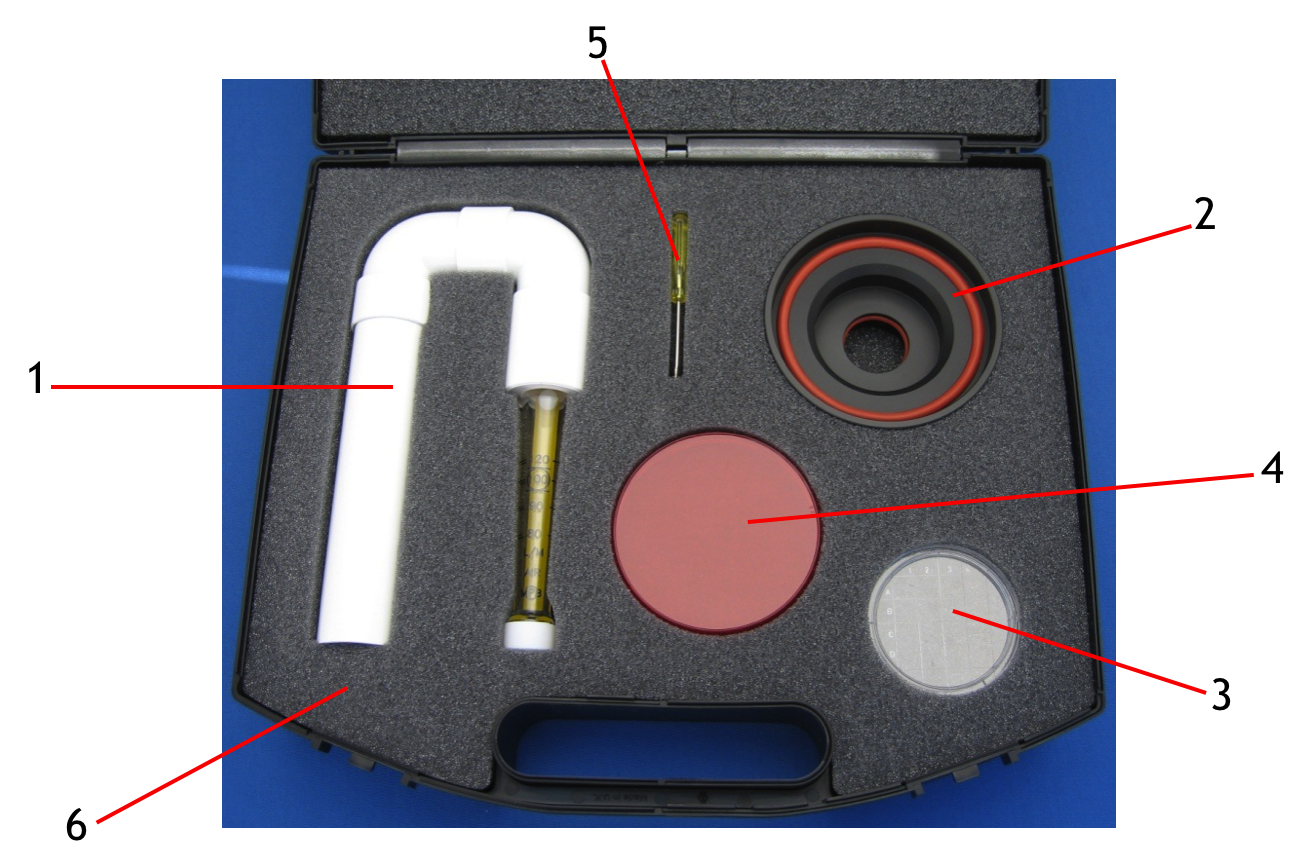

Kit Contents

Calibrated flow tube

Sampling head adaptor

Contact plate

Petri dish

Trimmer screwdriver

Padded plastic carry case

Factory calibration certificate (not shown in picture)

Setting Up

Tube and head adaptor assembly

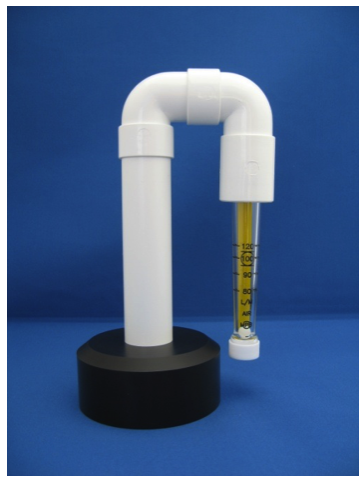

The first step is to insert the calibrated flow tube (1) into the head adaptor (2), as shown below. This forms the validation rig.

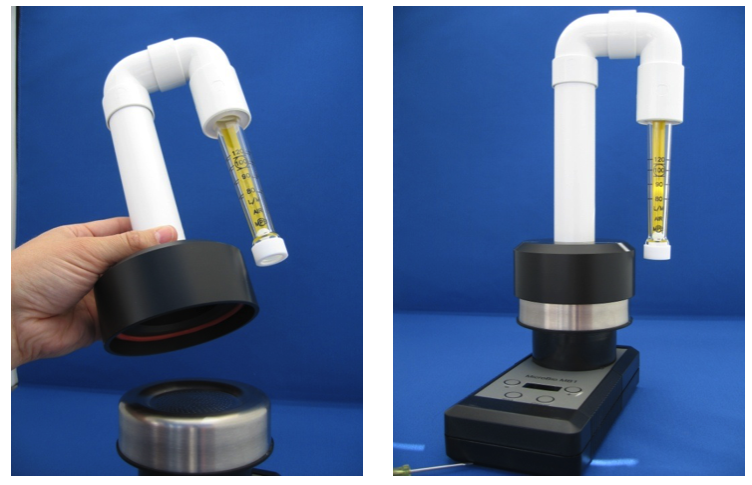

Preparing the air sampler

Fit the supplied Petri dish (4) or contact plate (3) into the MB1 or MB2 bioaerosol sampler to be validated and fit the sampling head. Then place the validation rig on top of the MB1 or MB2 as shown in below.

Validating the MB1 or MB2 bioaerosol sampler

Validation should be carried out in a controlled environment and on a level surface. Air movement around the calibration zone should be eliminated and ideally carried out in normal atmospheric pressure of 1013 mbar at 20°C.

Switch on the air sampler and set to take a volume of 400 litres. This will allow sufficient operating time for validation to be performed. Now start the sampler.

NOTE: MB2 users will need to initiate sampling operation before fitting the validation rig to the MB2 sampler.

The float will rise in the validation rig. Hold the validation rig down firmly onto the MicroBio sampling head or alternatively use quick grip clamps (not supplied) to hold in place. The float should centre on the circle printed on the glass tube indicating a flow rate of 100 litres per minute. Approximately 20 seconds should be allowed for the float to stabilise. There may be some occasional fluctuation of the float. If the float remains predominantly in the 100 litres per minute circle, the air sampler can now be considered validated.

NOTE: It is important not to obstruct the exhaust vents of the MB1 or MB2 sampler or the bottom of the glass tube of the flow rig during the validation test.

If the validation kit does not indicate correct flow, first check the rig is held firmly down and repeat the test. If the test fails a second time, the sampler should be returned to Cantium Scientific Limited or your local distributor for service and calibration.

Maintaining the Validation Kit

Due to the nature of variable area flow meters, as used in the validation kit and the product being manufactured to precise standards, annual calibration is not required. Regular inspection is needed. It is recommended that the validation kit is returned to Cantium Scientific Limited or an appointed re-seller for full factory inspection every five years.

When not in use, the kit should always be stored in the padded carry case and kept in a clean dry environment. The kit should be cleaned with a soft dry cloth. Inspection should include the following checks:

Ensure the orange coloured seals in the head adaptor (2) are clean, secure and level.

The calibrated flow tube (1) fits securely into the adaptor head (2).

Looking into the bottom of the glass tube check the white PTFE stopper is in-line with the direction of the tube and not at an angle restricting flow. If not, this can be moved into position using small pliers or tweezers.

The glass tube is parallel with the longer white plastic tube. If not, this can be moved into position by hand, as the silicone rubber fitting does allow a small degree of movement.

The glass tube is firmly fitted into the silicone rubber fitting.

If required, the kit can be returned to Cantium Scientific Limited or your local distributor for independent verification.

Additional Support

Further support for using the validation kit and the MicroBio MB1 and MB2 bioaerosol samplers can be obtained from Cantium Scientific Limited or your local distributor.

Documentation to support IQ/OQ/PQ for use within pharmaceutical and related industries is available upon request by contacting Cantium Scientific Limited, your local distributor, or our technical support portal.

Calibration of the Validation Kit

Calibration of the validation kit shall only be undertaken by Cantium Scientific Limited. It is recommended this is done at five yearly intervals.

Variable area flow meters impose a restriction on air flow. This will cause a reduction in the normal flow of air through the MB1 and MB2 bioaerosol samplers. Through experimentation during development, this restriction is known at various set-points on the tube scale and is compensated for on the flow markings on the tube.

The exact printing position on each tube is adjusted to take into account the equivalent true flow based on the known restrictions. Once printed, the tube is calibrated for life and no further adjustments are necessary.

Five year inspections will check the scale against the known restrictions using the same flow meter rig used during manufacture. This rig is a calibrated secondary standard held by the glass flow-tube manufacturer.

Calibration should be arranges through your local distributor or directly with Cantium Scientific Limited.