Dispensing Units

- Introduction

- Column Definitions

- Blinding Group

- Comparator

- Depot Shipment Cost per Kit

- Dispensing Unit Code

- Dispensing Unit Description

- Drug Products

- Drug Product Offset

- Do Not Dispense (DND)

- Do Not Count (DNC)

- Do Not Ship (DNS)

- Dynamic DND

- DNC Offset

- DNS Offset

- Fixed Production Cost per Lot

- Master Data

- Number of Kits per Storage Unit

- Packaging and Labeling Cost per Kit

- Pack Size

- Production Cost per Kit

- Production Lead Time

- Release Location

- Resupply Group

- Shelf Life

- Shipment Type Code

- Site Shipment Cost per Kit

- Stock Out Reporting Threshold

- Storage Cost per Month per Kit at Depot

- Storage Unit Code

Introduction

The Dispensing Units describe the kit types used in the model. The Dispensing Unit Code and Shelf Life are mandatory entries in this table.

Example Dispensing Units Table

Dispensing Units

Dispensing Unit Code |

Shelf life (days) |

Pack Size |

Drug Products |

Drug Product Offset (days) |

Shipment Type Code |

Storage Unit |

Blinding Group |

Resupply Group |

Release Location |

|---|---|---|---|---|---|---|---|---|---|

ACT_001 |

365 |

36 |

1 of DPA, 2 of DPB |

50 |

Cold Chain |

Box_S1 |

R1 |

C1 |

USA |

PBO_001 |

500 |

42 |

1 of PBA |

20 |

Ambient |

Box_S4 |

R2 |

C1 |

EUR |

Mandatory Attributes/Columns are in RED.

Note that this example only includes a limited number of the total available columns (listed alphabetically below).

Column Definitions

Blinding Group

Defines the blinding group a dispensing unit is associated with. Kits of dispensing units with the same blinding group are released together.

By default, all dispensing units in a study are associated with a different blinding group.

In forecast calculations with RTSM data extract, the blinding group specified for a kit type in the 4C Supply® specification defines the blinding group which will be used in the forecast calculation. If there is a mismatch between the blinding group in the RTSM and the blinding group in 4C Supply®, then the production planning algorithm used in the forecast calculation will group productions differently than in reality, which may lead to unblinding risks.

Definition of blinding groups is associated with multiple rules in other dispensing unit table columns and other tables:

Comparator

Defines whether a dispensing unit should be considered as comparator in cost modeling. Accepts values true, false, yes and no. If an invalid entry is made, no error is shown, but the value is ignored. The Default value is false.

Depot Shipment Cost per Kit

Defines the depot shipment cost per kit which is considered in the forecast calculation for production planning optimization and cost modeling. Must be a valid decimal number. If an invalid entry is made, no error is shown, but the value is ignored.

Must be a single decimal number. If more than one decimal is entered, a warning message is shown.

Can be overridden by specifying shipping and storage costs per kit at region and depot level.

Note: Cost parameters are not included in RTSM specifications and can/need therefore not be matched in forecast calculations with RTSM data extract.

Dispensing Unit Code

Defines the dispensing unit identifier for use in other tables. Dispensing unit code is a mandatory entry and each entry must be unique. If no dispensing unit code is specified, an error message is shown.

In forecast calculation with RTSM data extract, each dispensing unit code specified in 4C Supply® must map correctly to the corresponding kit type in the RTSM. This can be verified in the RTSM data extract mapping report.

Dispensing Unit Description

Details the description of the dispensing unit. This description is for informational purposes only and is not interpreted by the system.

Drug Products

Defines the number of drug product units needed to produce one dispensing unit. Entries must include a quantity and a valid Drug Product Code (as referenced in the Drug Products table) in the following format: ‘1 of DP_A’. Many-to-one relationships are also supported and may be declared as comma separated values.

Examples of valid entries:

‘2 of DP_A’

‘1 of DP_A, 1 of DP_B’

‘4 of DP_A, 2 of DP_B, 1 of DP_C’

In these examples ‘DP_A’, ‘DP_B’, and ‘DP_C’ are examples of valid drug product codes declared in the Drug Product table.

Drug Product Offset

Defines the production offset for a drug product. This value is interpreted as a number of days, so a valid positive integer is the only accepted input. An invalid input will return an interpretation error. This is an optional field, if no offset is input zero offset is assumed.

This offset enables drug product release dates to occur prior to Dispensing Unit release dates, this can be seen in the Production Plan report in the dedicated table (located below the standard production plan).

Do Not Dispense (DND)

Defines the number of days remaining shelf life a kit must have in order to be fit for dispensing. DND must be an integer. If an invalid entry is made, no error is shown, but the entry is ignored.

DNx values can be partially specified (for example, DND defined, but not DNC or DNS). This is allowed, but a warning message is shown.

If inconsistent DNx values (for example, DND > DNC > DNS) are specified, an error message is shown.

Dispensing units in the same blinding group must have the same DND value. If different DND values are specified for dispensing units in the same blinding group, the DND values are increased to the longest common DND value and a warning message is shown.

Notes

If not specified, 4C Supply® will compute the DND for all dispensing units as the longest interval of a dispensing visit.

If the DND is specified, but not the DNC or DNS, 4C Supply® will compute the DNC and DNS for each region and depot based on the specified DND and the respective lead times.

This column defines a static DND, it cannot be used with Dynamic DND has been defined as ‘True’ for a dispensing unit.

If used, a warning message will indicate the static value has been ignored.

See more DNx Details in Forecast Calculation Logic

Do Not Count (DNC)

Defines the number of days remaining shelf life a kit must have in order to be considered valid stock. DNC must be an integer. If an invalid entry is made, no error is shown, but the entry is ignored.

DNx values can be partially specified (for example, DNC defined, but not DND or DNS). This is allowed, but a warning message is shown.

If inconsistent DNx values (for example, DND > DNC > DNS) are specified, an error message is shown.

Dispensing units in the same blinding group must have the same DNC value. If different DNC values are specified for dispensing units in the same blinding group, the DNC values are increased to the longest common DNC value and a warning message is shown.

Notes

If not specified, 4C Supply® will compute the DNC for each region based on the DND and the respective site shipment lead times.

This column defines a static DNC, it cannot be used when Dynamic DND has been defined as ‘True’ for a dispensing unit.

If used, a warning message will indicate the static value has been ignored.

See more DNx Details in Forecast Calculation Logic

Do Not Ship (DNS)

Defines the number of days remaining shelf life a kit must have in order to be shipped to a site. DNS must be an integer. If an invalid entry is made, no error is shown, but the entry is ignored.

DNx values can be partially specified (for example, DNS defined, but not DND or DNC). This is allowed, but a warning message is shown.

If inconsistent DNx values (for example, DND > DNC > DNS) are specified, an error message is shown.

Dispensing units in the same blinding group must have the same DNS value. If different DNS values are specified for dispensing units in the same blinding group, the DNS values are increased to the longest common DNS value and a warning message is shown.

Notes

If not specified, 4C Supply® will compute the DNS for each depot based on the DND and the respective depot and site shipment lead times.

This column defines a static DNS, it cannot be used when Dynamic DND has been defined as ‘True’ for a dispensing unit.

If used, a warning message will indicate the static value has been ignored.

See more DNx Details in Forecast Calculation Logic

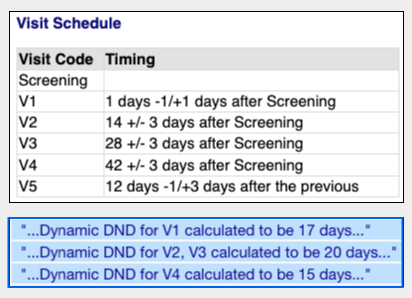

Dynamic DND

To use Dynamic DND, enter ‘True’ in the column labeled ‘Dynamic DND’ in the Dispensing Unit Table for that kit type.

During the forecast, the effective DND value used for any given dispensing will be calculated based on the anticipated date of the next visit with consideration of inner and outer visit windows.

Dynamic DND Calculation:

For visits anchored off of the previous visit, DND = visit interval length + outer window

i.e a visit schedule with 14 +/- 3 days from the previous has a DND of 17 days

For visits anchored off of a baseline visit, DND = visit interval length + inner window + outer window

i.e a visit schedule with 14 +/- 3 days from baseline has a DND of 20 days

Dynamic DND is set at the kit level, so a user can set one Dispensing Unit as Dynamic and another as a static DND.

Example: If the patient is dispensed an at-site injection along with a monthly kit to take home, the injection could be assigned a DND of 1 and the monthly kit could use a Dynamic DND.

A null or blank cell under ‘Dynamic DND’ will use a default value of False. If False, the system will either calculate a static DND (for all visits) using the max visit interval or take the user-defined value in the Dispensing Units Table.

Additional examples of Dynamic DND calculations:

V1: Anchored from the previous visit

Dynamic DND = V2 interval (14 days) + V2 outer window (3 days) = 17 days

V2: Anchored from the Screening visit

Dynamic DND = [V3 interval (28 days) + V3 outer window (3 days)] - [V2 interval (14 days) - V2 inner window (3 days)] = 31 - 11 = 20 days

V3: Anchored from the Screening visit

Dynamic DND = [V4 interval (42 days) + V4 outer window (3 days)] - [V3 interval (28 days) - V3 inner window (3 days)] = 45 - 25 = 20 days

V4: Anchored from the previous visit

Dynamic DND = V5 interval (12 days) + V5 outer window (3 days) = 15 days

DNC Offset

DNC Offset will only be used when Dynamic DND is set to ‘True’. The DNC Offset will be added to the calculation of the DNC. DNC Offset has a default value of 0.

DNC = Site Lead Time + max DND + DNC Offset

See more DNx Details in Forecast Calculation Logic

DNS Offset

DNS Offset will only be used when Dynamic DND is set to ‘True’. The DNS Offset will be added to the calculation of the DNS. DNS Offset has a default value of 1.

DNS = DNC + DNS Offset

See more DNx Details in Forecast Calculation Logic

Fixed Production Cost per Lot

Defines the production cost per lot which is considered in the forecast calculation for production planning optimization and cost modeling. Must be a valid decimal number. If an invalid entry is made, no error is shown, but the value is ignored.

Note: Must be a single decimal number. If more than one decimal is entered, a warning message is shown.

Master Data

Defines master data to be used for a given row. A valid MD item description must be entered in order for master data to be loaded and interpreted. See Master Data Rules.

Number of Kits per Storage Unit

Defines the number of kits which are stored in a storage unit. Must be an integer. Default value is 1. If an invalid entry is made, no error is shown, but the values is ignored.

Must be a single integer. If an invalid entry is made, an error message is shown.

Can be overridden by specifying shipping and storage costs per kit at region and depot level.

Cost parameters are not included in RTSM specifications and can/need therefore not be matched in forecast calculations with RTSM data extract.

Packaging and Labeling Cost per Kit

Defines the packaging and labeling cost per kit which is considered in the forecast calculation for production planning optimization and cost modeling. Must be a valid decimal number. If an invalid entry is made, no error is shown, but the value is ignored.

Note: Must be a single decimal number. If more than one decimal is entered, a warning message is shown.

Pack Size

To accurately reflect dispensing scenarios where units are shipped exclusively in fixed quantities, e.g., ten pre-filled syringes are shipped in a single box but dispensed individually, 4C Supply allows you to define a Pack Size for each Dispensing Unit in the Dispensing Units table. This ensures that the minimum shipment quantity is based on the defined pack size, making the pack size the smallest shippable quantity when a shipment is initiated.

The quantity of Dispensing Units defined in the Planned Lots table must be a multiple of the defined Pack Size. In specifications with a Planned Lots table, an error will appear in the interpreter log if a planned lot is not defined with a quantity that is a multiple of the defined pack size.

Planned Depot Shipments are an exception, they do not need to be entered as a multiple of Pack Size since they override the standard shipping forecast.

The same logic applies for outputs. If a production of 80 kits is required to account for the forecasted demand, and a pack size of 25 has been defined, 100 kits will be produced. The same logic applies to shipments, e.g., a site has a demand for 80 Dispensing Units and a Pack Size of 25 has been defined, then the forecasted shipment quantity will be 100.

In scenarios with actuals, a warning will appear in the RTSM Extract Loader logs when actual kits either In Transit at site/depot or Available at depot do not confirm to the specified pack size:

If the actual quantity of a shipment is greater than the defined pack size, the kit quantity will be rounded down to the closest multiple of the defined pack size.

If the actual quantity of a shipment is less than the defined pack size those kits will be ignored.

Pack Size is displayed in the following Output Reports with a column header ‘# of Packs’:

Forecasted Network Supply - Depot, Site Group, Actual Site, and Average Site levels

Forecasted Network Demand - Depot level

Forecasted Inventory - Depot level

Production Cost per Kit

Defines the production cost per kit which is considered in the forecast calculation for production planning optimization and cost modeling. Must be a valid decimal number. If an invalid entry is made, no error is shown, but the value is ignored.

Note: Must be a single decimal number. If more than one decimal is entered, a warning message is shown.

Production Lead Time

Defines an offset (in days) of the first date 4C Supply® will start producing lots. Accepts valid integers only, the default value is 30 days. In forecast calculations without an RTSM data extract, this is the Study Start date. In forecast calculations with RTSM data extract, this is the extract date.

In forecast calculations without an RTSM data extract: no production will be planned with release dates earlier than

Study Start + Production Lead Time.In forecast calculations with an RTSM data extract: no production will be planned with release dates earlier than

RTSM Extract Load Date + Production Lead Time.If no value is entered in the specification, the system will use a default value of 30 days.

Note: If no value is entered, 0 will display for Production Lead Time [Days] in the Materials input screen, but the system will use a default value of 30 days.

Example

In a study with low actual stocks at the production facility and an RTSM extract date in Oct-2020, 4C Supply® suggests an IMP batch release in Oct-2020 to cover demand if no production lead time is set (upper panes). By contrast, if a production lead time of 90 days is set (lower panes), the first computed batch release is scheduled in Jan-2021. Note that this causes stock-outs at the production facility.

Release Location

Defines the packaging and labeling location of a dispensing unit. Release Location is only mandatory if multiple network root nodes are defined in the Depots Table. If not specified although mandatory, an error message is shown.

Release Location must match an existing depot code defined in the Depots Table. If an invalid entry is made, an error message is shown.

Release Location must be a network root node. If an invalid entry is made, an error message is shown.

If a release location is also a depot which is supplied by another location, then two virtual locations have to be specified: a release location and a depot.

Example: If Depot USA is a release location and a depot, then:

one location (e.g. P&L USA) should be defined as release location and must not be supplied by other depots and

one location (e.g. Depot USA) should be defined as depot and can be supplied by other depots.

Note: If multiple release locations are specified, the Network input screen is displayed filtered by kit type.

Resupply Group

Defines the resupply group a dispensing unit is associated with. Kits of dispensing units with the same resupply group are shipped together.

By default, all dispensing units in a study are associated with the same resupply group.

In forecast calculations with RTSM data extract, the resupply group specified for a kit type in the 4C Supply® specification defines the resupply group which will be used in the forecast calculation. If there is a mismatch between the resupply group in the RTSM and the resupply group in 4C Supply®, then the resupply algorithm used in the forecast calculation will group shipment contents differently than in reality, which may cause incorrect forecast calculation results.

Note: Dispensing units in the same blinding group must be in the same resupply group. If different resupply groups are specified for dispensing units in the same blinding group, an error message is shown.

Shelf Life

The shelf life specified for a kit type in the 4C Supply® specification defines the shelf life which will be allocated to batches in planned productions. It is duration (days) from release (or Production Plan date) of a finished IMP batch in a study to expiry. Must be an integer and is a mandatory entry. If an invalid entry is made, an error message is shown.

Dispensing units in the same blinding group must have the same shelf life. If different shelf lives are specified for dispensing units in the same blinding group, the shelf lives are trimmed to the shortest common shelf life and a warning message is shown.

Notes

4C Supply® computes the shelf life for each forecasted lot according to the shelf life specified for the corresponding dispensing unit.

4C Supply® assumes that kits from a batch can be distributed in the study from the day of release and used by patients in the study until the do not dispense date.

Expiry Dates defined for existing and planned lots will override the shelf life defined for the corresponding dispensing unit.

Shipment Type Code

Defines the shipment type which is used to ship kits of a dispensing unit. Must match a shipment type code specified in the shipment types. If an invalid entry is made, an error message is shown.

Site Shipment Cost per Kit

Defines the global site shipment cost per kit which is considered in the forecast calculation for production planning optimization and cost modeling. Must be a valid decimal number. If an invalid entry is made, no error is shown, but the value is ignored.

Must be a single decimal number. If more than one decimal is entered, a warning message is shown.

Can be overridden by specifying shipping and storage costs per kit at region and depot level.

Cost parameters are not included in RTSM specifications and can/need therefore not be matched in forecast calculations with RTSM data extract.

Stock Out Reporting Threshold

Defines the threshold that will be used in the Stock Out Risk report. The default value is ‘0.5’ kits, meaning that the report will only display risk when there is a stock out of risk equal to or more than 0.5 kits. Entering a threshold value of less than 0.5 will result in the report including lower stock out quantities.

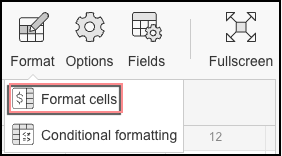

Note: The Stock Out Risk report is configured to report whole numbers by default, so in addition to setting a custom Stock Out Reporting Threshold it will also be necessary to update the report configuration to display decimal places, this can be configured via Format > Format Cells > Decimal Places.

Note: The Stock Out Risk report is configured to report whole numbers by default, so in addition to setting a custom Stock Out Reporting Threshold it will also be necessary to update the report configuration to display decimal places, this can be configured via Format > Format Cells > Decimal Places.

Storage Cost per Month per Kit at Depot

Defines the storage cost per kit per month. Must be a valid integer or decimal value. If an invalid entry is made, no error is raised, but the specified value is ignored. Must be a single value. If an invalid entry is made, a warning message is shown.

Note: It is advised not to specify storage units / kits per storage unit and storage costs per month per kit as this will lead to consideration of two storage cost types per kit in the forecast calculation.

Storage Unit Code

Defines the storage unit which is used to store kits of a dispensing unit. Must match a storage unit code specified in the storage units. If an invalid entry is made, no error is shown, but the value is ignored.

Can be overridden by specifying shipping and storage costs per kit at region and depot level.

Cost parameters are not included in RTSM specifications and can/need therefore not be matched in forecast calculations with RTSM data extract.