Forecast Calculation Logic

- Overview

- Order of Calculations

- Example Patient Demand Calculation

- Site Resupply Calculations

- Depot Resupply Calculations

- Production Calculations

- Risk Index

- DNx Parameters

- Terminology

- Correlated Unpredictable Demand (CUD)

- Depot Long Window

- Depot Resupply Shipment Trigger

- Depot Short Window

- Enrollment Buffer

- RTSM Parameter update interval

- Patient in Treatment Buffer

- Predictable Demand (PD)

- Production Facility

- Production Lead Time

- Shelf Life

- Site Buffer

- Site Ceiling

- Site Demand

- Site Long Window

- Site Resupply Shipment Trigger

- Site Short Window

- Uncorrelated Unpredictable Demand (UUD)

Overview

This page describes how 4C Supply® computes a forecast. The most important difference between this tool and many others on the market is that does not rely on simulation but arrives at similar results to that of a very high iteration simulation via a statistical approach.

Simulation vs Statistical Forecasting

Simulation

The realizations (or ‘observed values’) in simulations will display (by using a distribution fitting) as a normal distribution (or bell curve).

Statistical

Because we can assume that Simulations will always result in a Normal Distribution, we are able to “skip” a time consuming simulation process and apply this same theoretical distribution for the statistical forecast calculations.

Variability

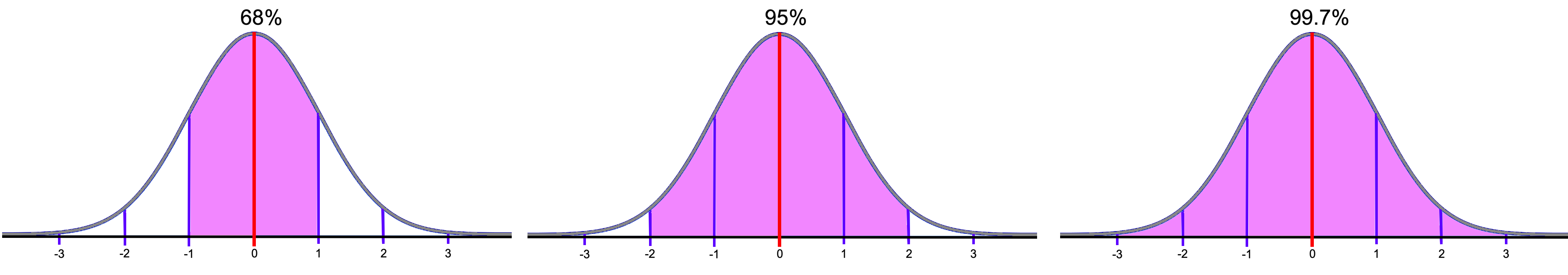

The variability (i.e., min and max values) displayed in the Output Reports are directly related to the confidence interval. The confidence interval can be defined either by using the confidence dial on the Calculation page or as Confidence Used for Site Buffers in the Demand Configuration specification table.

A higher confidence interval will lead to a larger spread between the min, average, and max values.

A lower confidence interval will result in min and max values that are closer to the average values.

Since the dial only allows inputs between 50% and 99% buffer confidence, users are only able to cover average + x standard deviations on enrollment/demand:

Average + 1 standard deviation = 68% dial setting

Average + 2 standard deviations = 95% dial setting

Average + 3 standard deviations = 99% dial setting

Visual representation of how the confidence dial setting covers different levels of demand

Buffer Coverage

Looking at the normal distribution curve above, the line in the middle of the curve represents average demand. When 4C Supply® calculates the resupply buffer, it will consider demand between average & max. The precise value used is determined by the confidence setting selected. This value is represented by a dotted green ‘buffer coverage’ line on the Patient Enrollment and Patient Net Demand reports.

At 50% it aligns with the average enrollment/demand

At 99% it aligns with the max enrollment/demand

Therefore, buffer coverage really means the percent of possible demand that is buffered for, between the average and theoretical max.

Order of Calculations

Single patient demand based on the dispensing plan

Site activation at site group level

Patient enrollment at site group level

Total Patient demand at site group level

Resupply at site level and then going up the network though depots to the central depot.

Single Patient Demand

Patient Demand is calculated using the probability of the patient’s dispensing options that will occur in that calculation period.

Site Activation

Site Activation uses a Normal Distribution to calculate the number of sites (in a Site Group) that are opened each month.

Patient Enrollment

Patient Enrollment also uses a Normal Distribution and is calculated at the Site Group Level. It is the product of the number of open sites and the number of patients per site.

Total Patient Demand

Total demand is the demand for a single patient multiplied by the number of patients at the site group level.

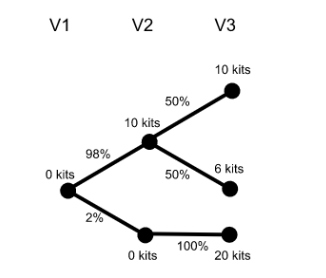

Example Patient Demand Calculation

In this case, probabilities of dispensing by visit are:

V1 = 0 kits: 100%

V2 = 0 kits: 2%, 10 kits: 98%

V3 = 20 kits: 2%, 6 kits: 49%, 10 kits: 49%

For each visit, the smallest value that has more than 95% chance of being dispensed is:

V1 = 0 kits

V2 = 10 kits

V3 = 6 kits

This is the Predictable Demand.

Max on demand depends on the confidence dial we set in the UI. In this case, if the dial is set above 98%, max unpredictable demand is the maximum demand minus predictable demand:

V1 = 0 kits

V2 = 0 kits

V3 = 14 kits

Site Resupply Calculations

Initial Shipment Quantity

Maximum forecasted total demand in Short Window + Average forecasted total demand in Long Window.

Site Buffer (Floor) Quantity

The Floor can be defined by the user in the RTSM Parameters Table in the SMART Editor. If the Floor is not user-defined, 4C Supply® will use the below calculations:

If Site Resupply Logic is Buffer + Prediction, Site Buffer = Maximum forecasted Unpredictable Demand in the site Short Window

If Site Resupply Logic is Buffer Only or Prancer RTSM, Site Buffer = Maximum forecasted Total Demand in the site Short Window

If the Additional Buffer is defined in the ‘Minimum and additional buffer at Site’ Table, this buffer is added to the Site Buffer. Then, if the Minimum Buffer is defined, and it is greater than the calculation value above, it will use the Minimum Buffer Value instead.

Site Resupply Shipment Trigger

If the scenario does not have a user-defined Floor (using the RTSM Parameters Table in the SMART Editor), the resupply order is triggered when the site inventory is:

less than the Floor/Buffer for 'Buffer Only' Logic or

less than the Floor/Buffer + Max Predictable Demand in Short Window for 'Buffer + Prediction' Logic

If the User defines the Floor in the RTSM Parameters Table, the resupply order is triggered when the site inventory is:

less than the user-defined Floor for 'Buffer Only' Logic or

less than the user-defined Floor + Max Predictable Demand in Short Window for 'Buffer + Prediction' Logic

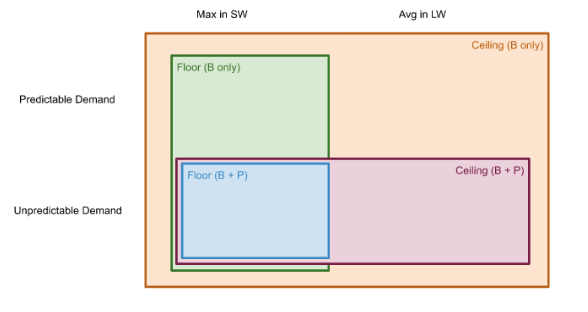

Resupply Shipment Quantity

If a site resupply order is needed, 4C Supply® computes the shipment contents for each kit type in the resupply group as:

Buffer + Prediction Site Resupply Logic

Floor = Max (Short Window UUD + Short Window CUD)

Ceiling = Floor + Avg Long Window UUD + Avg Long Window CUD

Supply = Ceiling + Max Short Window PD + Avg Long Window PD - Site Inventory

Buffer Only Site or Prancer RTSM Resupply Logic

Floor = Max Short Window demand

Ceiling = Floor + Avg Long Window Demand

Supply = Ceiling - Site Inventory

Max Short Window demand = Max (Short Window UUD + Short Window CUD + Short Window PD)

Avg Long Window demand = Avg Long Window UUD + Avg Long Window CUD + Avg Long Window PD

For all site resupply logics (and when the RTSM Parameters are not defined by the user for the Buffer + Prediction Logic and Buffer Only Logic), the RTSM Parameter Update Interval is used to update the floor/ceiling values used throughout the forecast. Based on what the user selects, we take the max floor/ceiling value over either monthly, quarterly or yearly intervals after they are computed using the above calculations (defaults to monthly). For example, if a period begins Jan 1, we have a monthly update parameter, and a max ceiling value over the month of 10 kits on Jan 15, then our ceiling throughout the month of January is 10 kits. The same process occurs with the floor.

If we are using Prancer RTSM resupply logic, we additionally round the floor/ceiling up to the nearest multiple of the median dispensing. For example, if we only dispense kits 2 at a time, the ceiling/buffer will be rounded up to a multiple of 2.

Depot Resupply Calculations

Depot Demand Quantity

During the forecast calculation, 4C Supply® computes the demand for each period, for each depot and for each kit type as the sum of kits leaving the depot in orders from sub-depots and sites.

Depot Demand = sum of all demand from sites and depots for which the current depot supplies.

Depot Buffer

Depot Buffer = max of (sum of site demands over Depot Short Window + sum of sub-depot demands over Depot Short Window) + Additional Buffer (if user-defined) in the Depot Short Window. If the Minimum Buffer is defined in the ‘Minimum and additional buffer at Depot’ Table, and it is greater than the calculation value above, it will use the Minimum Buffer Value instead.

Depot Shipment Quantity

If a depot order is needed, 4C Supply® computes the shipment contents for each kit type in the resupply group as:

Supply = Depot demand over Long Window + depot buffer demand - site inventory

Production Calculations

Production Interval Calculation

Shelf Life and Do Not Ship (DNS) are two contributing factors that should be considered when selecting a Production Interval. If the Production Interval is not user-defined, 4C Supply® will use the following calculation:

Production Interval = (Shelf Life - Max DDNS) / 2

where Max DDNS is the maximum DNS value at the production facility (considering the longest lead times from production facility to site and visit interval). Any Production Interval greater than that calculated above could result in release quantities that cover demand in periods where kits enter DNS. In instances where demand is lower than what’s forecasted, there is also a risk that kits produced will not progress down the supply chain or reach DNS. Therefore, the Production Interval is decreased by half of the Shelf Life minus DDNS value calculated.

Initial production can begin as early as the maximum lead time from the earliest site group start date to the production facility (typically identical in total lead time to the central depot), or 30 days before Study Start Date if that date occurs first. With actuals, the Production Lead Time value is used solely to determine how early production can start after the extract date. It defaults to 30.

Production Quantities

To ensure that there is always adequate inventory to cover maximum central depot demand over the short window, 4C Supply creates and releases production quantities at the Production Facility at the nearest production interval anytime the central depot inventory falls below the maximum demand in the Release Short Window.

Production Quantity (for each release) = Max Demand in the short window + Avg Demand in the Production Interval (Production Long Window)

Countable inventory

Countable inventory = inventory which will not expire in the resupply short window

Risk Index

The risk index is intended to be used as a comparative measure of risk between scenarios, or as an indicator of scenario misconfiguration (e.g. due to overly restrictive DNx values or Production Interval). The risk index at a given time for a given site/depot and kit is the proportion of unsatisfied demand in the worst case scenario at that time, divided by the total demand over the entire study.

Risk Index t = (Min Usable Inventory t - Max Demand t ) / Total Avg Demand

DNx Parameters

If not specified in the dispensing units table, DNx parameters are computed by 4C Supply® as follows:

DNDdispensing unit = max visit interval

DNCdispensing unit, region = SLTregion + DNDdispensing unit

DDNCdispensing unit, depot = SLTdepot + max (D)DNS to subordinate site/depot

DNSdispensing unit, region = DNCdispensing unit, region + 1

DDNSdispensing unit, depot = DDNCdispensing unit, depot + 1

With Dynamic DND enabled, the DNx values have been adapted from definitions of static DNx, except that instead of static DND we use the dynamic next visit offsets to decide if we can dispense kits at sites, Next Usage t, and additional DNC/DNS Offsets :

Next Usage t = time of next demand considered by 4C + maximum possible delay of that visit OR for the last dispensing visit, then the maximum possible delay of the EOT visit

DNDdispensing unit = Next Usage t

DNCdispensing unit, region = SLTregion + max DNDdispensing unit + DNC OFFSETdispensing unit (default=0)

DDNCdispensing unit, depot = SLTdepot + max (D)DNS to subordinate site/depot

DNSdispensing unit, region = DNCdispensing unit, region + DNS OFFSETdispensing unit (default=1)

DDNSdispensing unit, depot = DDNCdispensing unit, depot + DNS OFFSETdispensing unit (default=1)

Terminology

Correlated Unpredictable Demand (CUD)

Demand which is not 100% certain (for example, titrations, weight-based dispensing, etc.)

Depot Long Window

The Long Window is the Prediction Window Defined in the Supply Configuration Tab or Table in the SMART Editor. Long Windows can be defined separately for each depot.

Depot Resupply Shipment Trigger

Depot shipments are triggered when the depot inventory is less than the depot buffer.

Depot Short Window

If a Short Window is not Defined in the Depot Network Table, 4C Supply® will use the Lead Time defined in the Depot Network Table.

Enrollment Buffer

Enrollment buffers are computed to cover the maximum enrollment (per selected confidence interval) in the Short Window.

RTSM Parameter update interval

Interval at which to update floor / ceiling values at sites after they have been computed using outline calculations. It defaults to monthly. Update this in the Supply Configuration table in the SMART Editor to select ‘Quarterly’ or ‘Yearly’ options.

Patient in Treatment Buffer

The sum of max Correlated Unpredictable Demand (CUD) and the max Predictable Demand (PD) of all enrolled patients at a site in the Short Window.

Predictable Demand (PD)

Demand which has a probability highest than 95% (configurable) of occurring (fixed dispensing).

Production Facility

The facility at which production occurs. It is automatically created for each root depot with a default lead time of 0.

Production Lead Time

The Production Lead Time in the Dispensing Units Table is used only with actuals to determine how soon production can begin after the extract date. If not user-defined, the default value is 30 Days.

Shelf Life

Defined by the user, it is the remaining shelf life of the Dispensing Unit at the time of the production release.

Site Buffer

The Maximum patient demand of each kit type in the site Short Window. Site Buffer can also be referred to as the Floor or Site Safety Stock. To manually define the Floor, use the RTSM Parameters Table in the SMART Editor.

Note, a Floor can only be defined for a ‘Buffer + Prediction’ or ‘Buffer Only’ Resupply Logic.

Site Ceiling

Used in the ‘Buffer + Prediction’ or ‘Buffer Only’ Resupply calculations. To manually define the Ceiling, use the RTSM Parameters Table in the SMART Editor.

Note, a Ceiling can only be defined for a ‘Buffer + Prediction’ or ‘Buffer Only’ Resupply Logic.

Site Demand

The Site Demand is the total Patient Demand (at that site) for that period.

Site Floor - See ‘Site Buffer’

Site Long Window

The Long Window is the Prediction Window Defined in the Supply Configuration Tab or Table in the SMART Editor. Site Group Long Windows can be defined separately for before LPI and after LPI. Long Windows can be defined separately for each site group.

Site Resupply Shipment Trigger

During forecast calculation, 4C Supply® computes for each day in each period, for each site and for each kit type whether a site resupply is needed. If the site inventory on a given day is less than the required site buffer level (or Floor) for that day, then a site shipment is forecasted to be sent.

Site Short Window

If a Short Window is not Defined in the Site Network Table, 4C Supply® will use the Lead Time defined in the Site Network Table. For the details below, the term ‘Short Window’ will be used.

Uncorrelated Unpredictable Demand (UUD)

Anticipated demand from enrollment of future patients.