Risk Index

Introduction

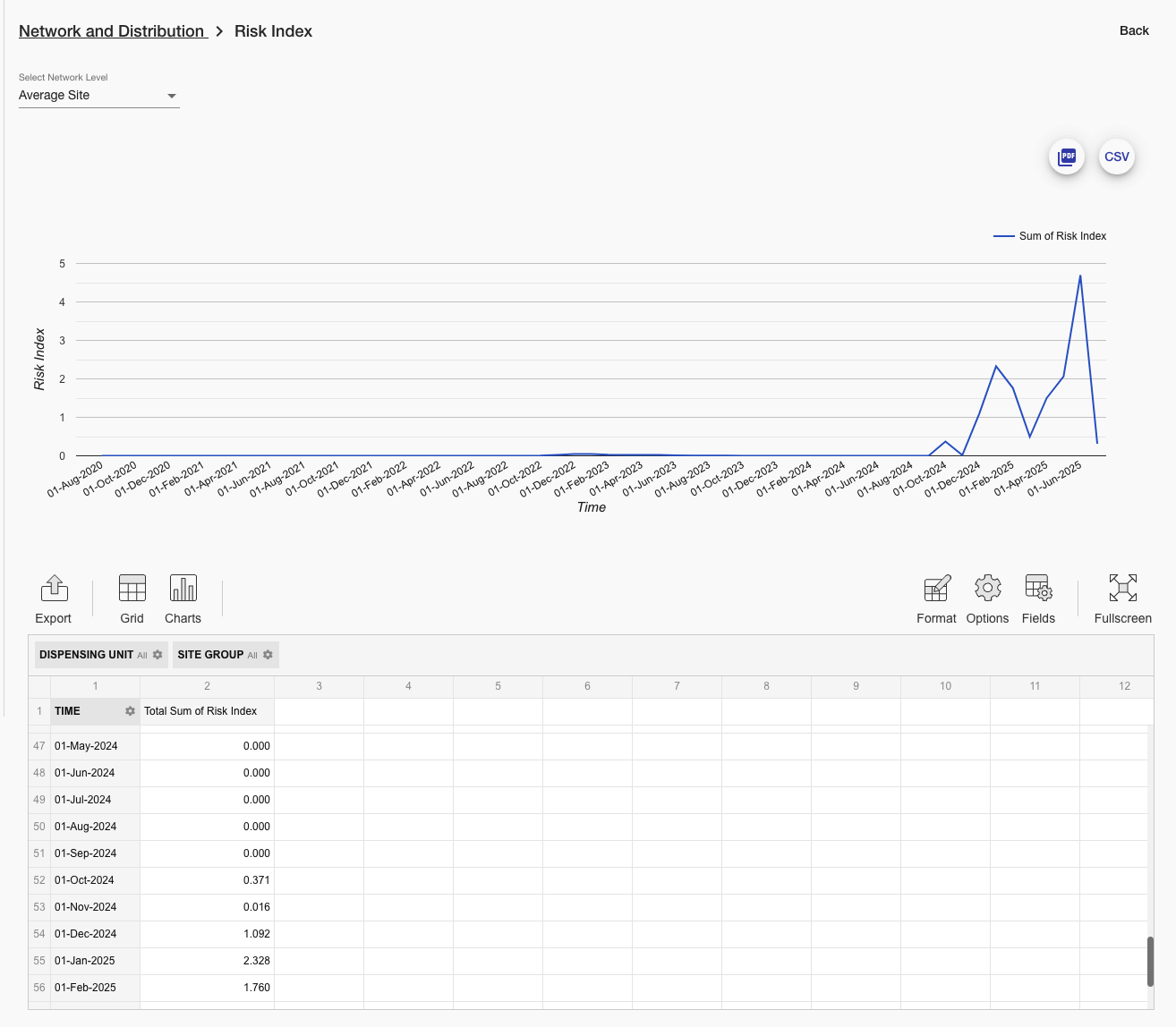

The Risk Index report shows the proportion of unsatisfied demand in the worst-case scenario at a given time, divided by the total demand over the entire study. The risk index is calculated at every network level, kit type, and time point as the proportion of unmet demand to total demand weighed against the likelihood of that out-of-stock event occurring. See this entry on the calculation of risk for more detail.

Risk values of less than 0.1 will produce warning messages only.

Risk values greater than 0.1 will be reported as errors.

As with other log messages, it is best practice to review all warnings and errors to ensure your study is set up as expected.

A value greater than 1 indicates a significant risk of an out-of-stock occurring and may point to a configuration issue.

The report data can be shown for either Depots or for Site, as determined by the report selector (i.e., the Select Network level dropdown).

Example

Example risk index report with low risk for most of the duration and very high risk incurred towards the end of the study

Fields and Filters

Example of the fields selector for Risk Index when Depot is the selected level

Depot

Determines for which depot(s) data is shown in the report.

Only shown when Depot is selected as the network level.

Dispensing unit

Defines the dispensing unit(s) for which the risk index is shown.

Risk Index

Defines both the magnitude and likelihood of an out-of-stock occurring by period for a given depot or site. See this entry on the calculation of risk for more detail on how risk is calculated.

Site Group

Determines for which site group(s) data is shown in the report.

Only shown when Site is selected as the network level.

Time

Defines the periods for which the risk index is calculated.