Forecast Overview

Overview

The Forecast Overview report provides a synopsis of the forecast calculation inputs and outputs. This report features the following sections:

The first section summarizes the configuration parameters.

The second section reports patient demand and production plan data.

The third section reports forecasted study costs, logistics, and total scraps.

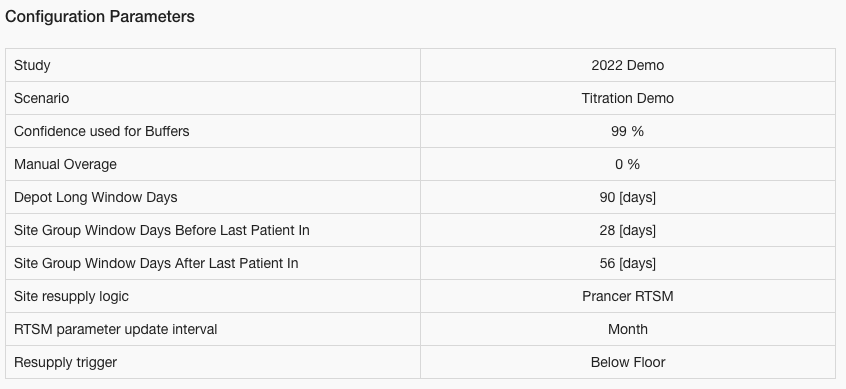

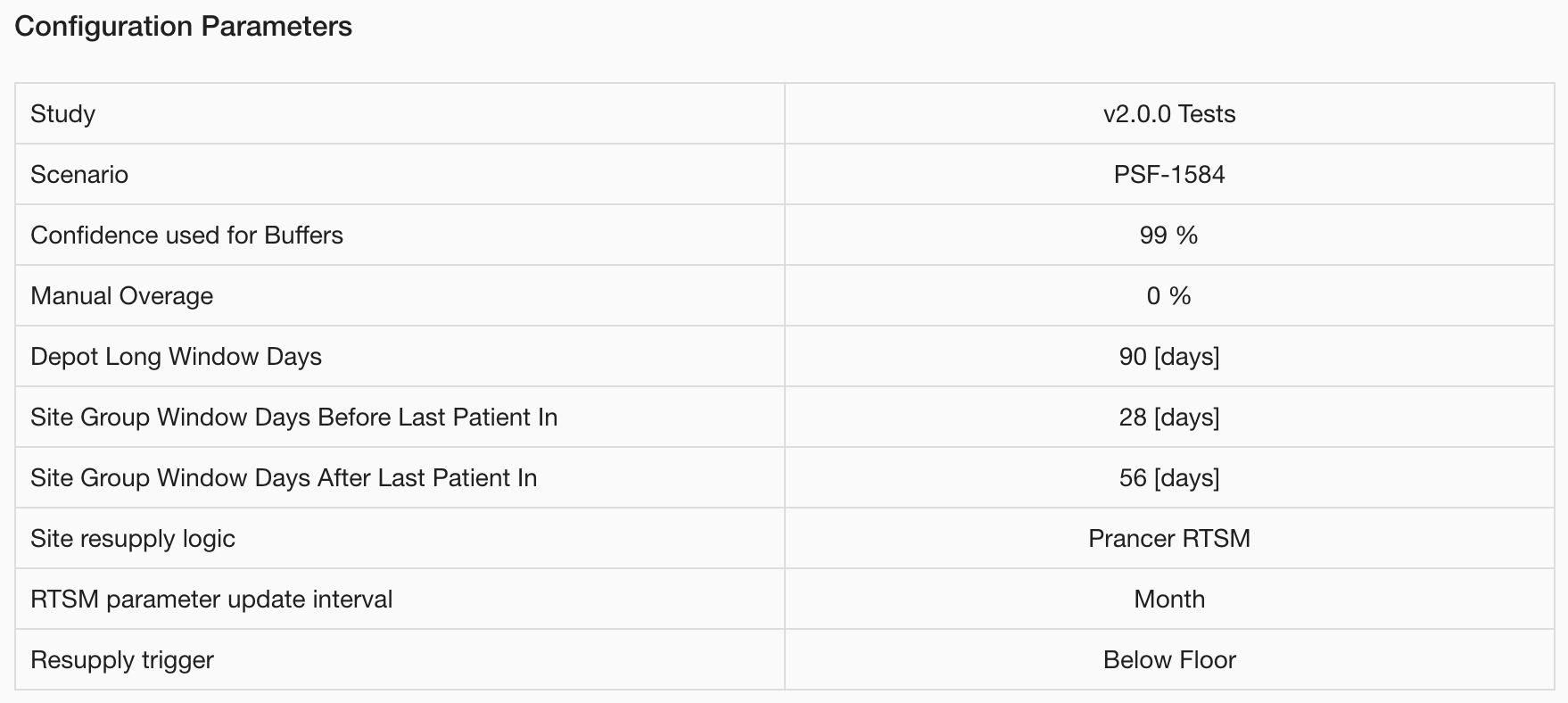

Configuration Parameters

Specifies the inputs of a forecast calculation, including:

Study, Scenario, and (if applicable) RTSM extract details

Forecast configuration settings

RTSM and resupply settings

Note: Only ‘top-level’ demand configuration settings (i.e., global depot long window, not depot long window per depot) are reported here, more detail can be found in the Calculation page.

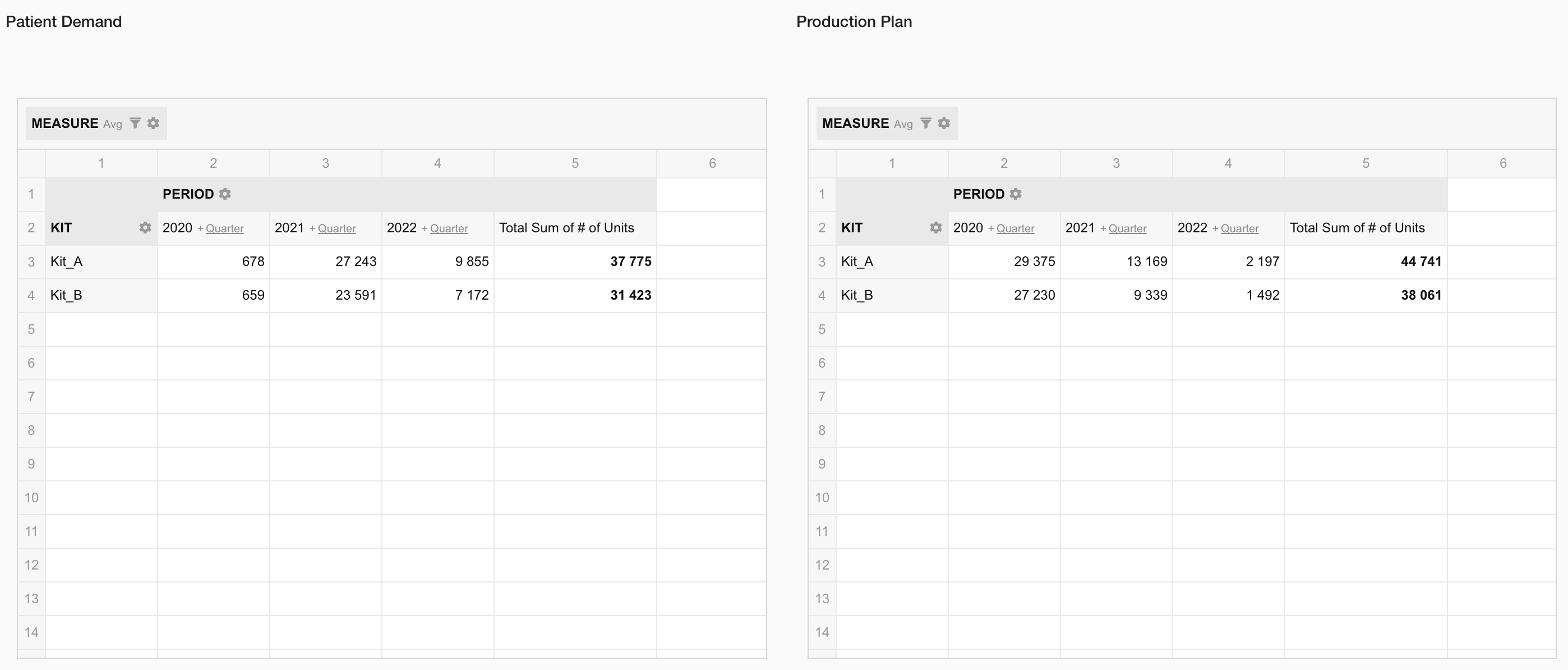

Patient Demand

Provides a synopsis of the patient net demand report.

Periods are shown as columns by default.

Only average data is shown by default (can be filtered to show Min or Max using the Measure Filter).

Dispensing units are shown as rows by default.

Production Plan

Provides a synopsis of the production plan report.

Periods are shown as columns by default. Use the '+' option to drill down into shorter periods.

Only average data is shown by default (can be filtered to show Min or Max using the Measure Filter).

Dispensing units are shown as rows by default.

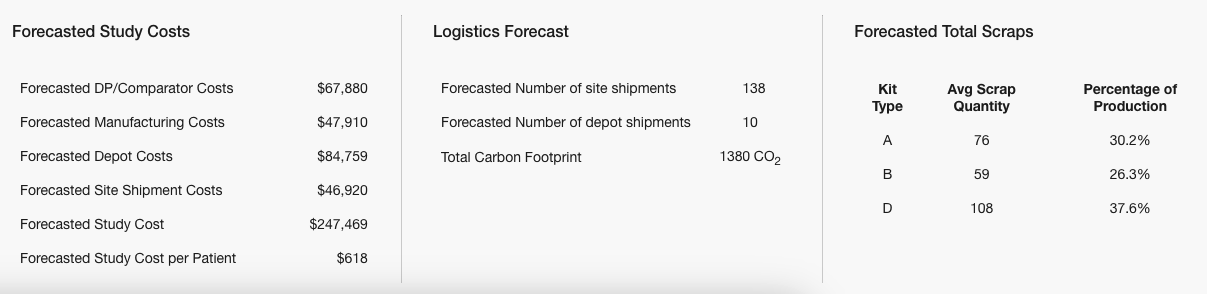

Forecasted Study Costs

Provides a synopsis of the forecasted study cost report.

Shows total of forecasted drug product and comparator costs.

Shows total of forecasted manufacturing costs.

Shows total of forecasted depot costs.

Shows total of forecasted site shipment costs.

Shows estimate of total forecasted study cost.

Shows total of forecasted study cost per patient.

Logistics Forecast

Shows a synopsis of the forecasted depot shipments report and the forecasted level shipments report.

Shows total depot shipments.

Shows total site shipments.

Shows total shipping emissions.

Forecasted Total Scraps

Shows the relation between kits expected to be produced, but not allocated and total kits.

Forecasted total scrap = (produced kits - allocated kits) / produced kits